Inventory management is the cornerstone of efficient and profitable business operations. The way a company manages its inventory can impact customer satisfaction and success. To navigate inventory management, businesses must establish clear goals and objectives. This guide will explore inventory management goals and objectives that can help businesses optimize their inventory processes.

Inventory Management

Before discussing inventory management goals and objectives, let’s understand what inventory management is.

Defining Inventory

Inventory encompasses all the goods and raw materials that a business holds for various purposes. This can include ready-for-sale products, raw materials used in production, and spare parts.

Why Inventory Management Matters?

Effective inventory management is more than keeping track of your stock. It’s about ensuring that you have the right products in the right quantities at the right time. This, in turn, has several critical implications for your business:

Operational Efficiency:

Well-managed inventory keeps your operations running by preventing stock outs and overstock situations.

Financial Impact:

Your company’s financial health depends on how you manage inventory. Holding excess inventory ties up capital and incurs storage costs. But, insufficient inventory can result in lost sales opportunities.

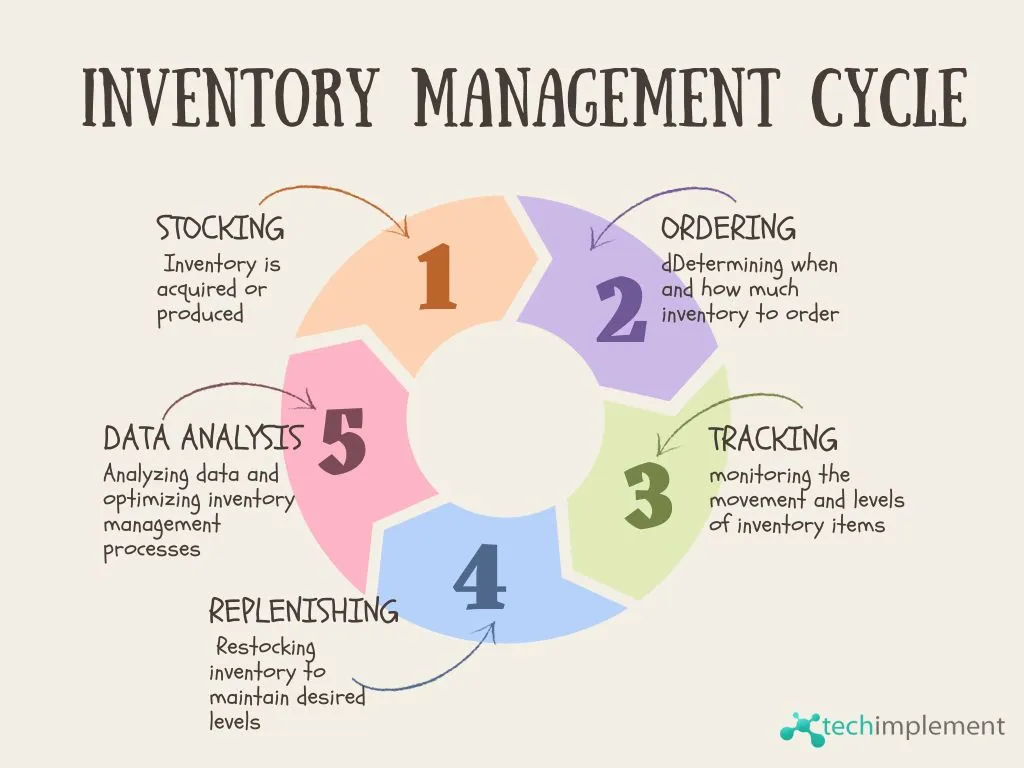

Inventory Management Cycle

Inventory management involves a continuous cycle:

1. Stocking

This is the initial phase where inventory is acquired or produced.

2. Ordering

The ordering involves determining when and how much inventory to order.

3. Tracking

Inventory tracking monitors the movement and levels of inventory items. It helps in identifying trends and potential issues.

4. Replenishing

Replenishment involves restocking inventory to maintain desired levels. This can include reorder points, safety stock, and economic order quantities (EOQ).

5. Data Analysis

The final step involves analyzing data and optimizing inventory management.

Inventory Management Goals

To excel in inventory management, businesses need to set clear and achievable goals. Here are some essential inventory management goals to consider:

1. Minimizing Costs

- Cost Reduction Strategies

Implementing strategies to reduce inventory costs is a fundamental goal. This includes minimizing holding costs, optimizing storage space, and reducing waste.

- Optimizing Reorder Points

Determining the ideal time to reorder inventory is crucial. Setting accurate reorder points ensures that you restock on time. This minimizes excess inventory costs.

2. Maximizing Efficiency

- Streamlining Processes

Efficiency is the name of the game. Streamlining your inventory-related processes can save time, resources, and manpower.

- Reducing Stock outs

Stock outs can lead to unhappy customers and missed revenue. Ensuring that products are available when needed is the main goal.

3. Enhancing Accuracy

- Inventory Accuracy

Accurate inventory counts are essential for making informed decisions. This includes maintaining correct records and conducting regular audits.

- Data Integrity

Maintaining data accuracy in inventory management systems is crucial. Inaccurate data can lead to costly errors and mismanagement.

4. Managing Inventory Turnover

- Understanding Turnover

Inventory turnover measures how you sell or use up your inventory within a specific time. A higher turnover rate generally indicates efficient inventory management.

- Managing Obsolete Inventory

Dealing with slow-moving or obsolete inventory items is a common challenge. Implementing strategies to cut losses is an important goal.

Objectives for Effective Inventory Management

After setting goals, businesses should establish specific objectives to guide their efforts:

1. Demand Forecasting

- Accurate demand forecasting ensures that you have the right inventory levels to meet customer demand.

- Handling seasonal fluctuations in demand requires a nuanced approach. Effective demand forecasting can help you plan for these variations.

2. Safety Stock

- Determining the level of safety stock is important for avoiding stock outs.

- Safety stock acts as a buffer against uncertainties in supply and demand. It helps maintain a consistent flow of products.

3. Supplier Relationships

- Strengthening your relationships with key suppliers can lead to more favorable terms. It provides better lead times and improved reliability.

- Evaluating and monitoring supplier performance ensures that your suppliers deliver quality products.

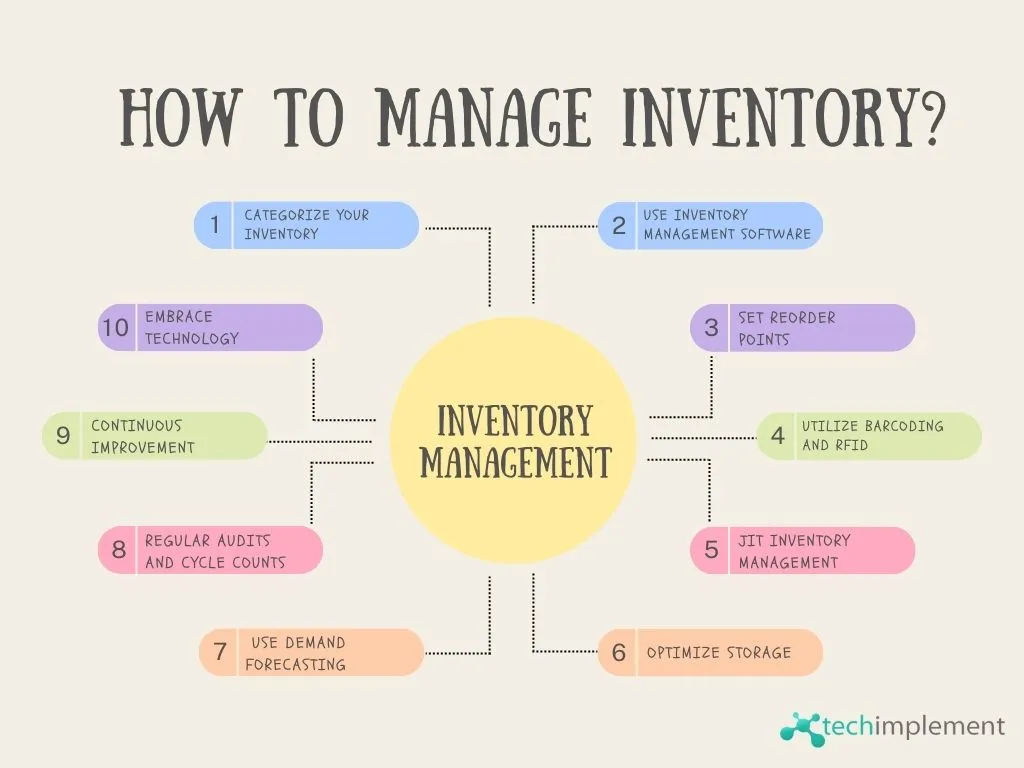

How to Manage Inventory?

After discussing inventory management goals and objectives, let’s delve into how to manage it. Inventory management is a critical component of running a successful business. Managing your inventory can help you optimize costs and ensure smooth operations. Here are various strategies and approaches to manage your inventory:

1. Categorize Your Inventory

ABC Analysis:

Divide your inventory into categories based on value or importance. “A” items are the most valuable and “C” items are the least.

Product Types:

Categorize items by type, such as raw materials, finished products, or spare parts. Each category may need different management strategies.

2. Use Inventory Management Software

Choose the Right Software:

Invest in inventory management software that suits your business needs. It should provide real-time tracking, reporting, and integration with other systems.

Automation:

Use software to automate routine tasks, such as reordering and data entry. This reduces human error and saves time.

3. Set Reorder Points

Determine Reorder Points:

Calculate reorder points for each item based on factors like lead time and safety stock. When inventory reaches these points, trigger reorder actions.

Safety Stock:

Maintain a buffer of safety stock to handle unexpected demand spikes or delays.

4. Use Barcoding and RFID

Barcoding:

Install barcode systems for easy and accurate tracking of items. This simplifies data entry and reduces errors.

RFID (Radio-Frequency Identification):

Use RFID technology for real-time tracking, improving traceability, and enhancing security.

5. Just-in-Time (JIT) Inventory Management

Apply JIT Principles:

Adopt JIT practices to reduce excess inventory levels. Order and receive goods only as needed for production or sale.

Supplier Collaboration:

Work with suppliers to ensure timely deliveries and cut holding costs.

6. Optimize Storage and Warehouse Practices

Organize Your Warehouse:

Arrange items to ease access and efficient inventory control. Apply labeling and zoning systems.

Reduce Overstock and Obsolete Items:

Review and address slow-moving or obsolete inventory. Consider offering discounts or promotions to clear excess stock.

7. Use Demand Forecasting

Accurate Predictions: Use historical data and market trends to make precise demand forecasts. This minimizes overstocking or understocking.

Seasonal Variations: Consider seasonal fluctuations in demand when planning inventory levels and promotions.

8. Regular Audits and Cycle Counts

Periodic Audits:

Conduct regular physical audits to ensure that your actual inventory matches your records. Correct discrepancies.

Cycle Counts:

Use cycle counts, focusing on different items or categories each time.

9. Continuous Improvement

Key Performance Indicators (KPIs):

Define and check KPIs like inventory turnover ratio, fill rate, and stock out rate. Use these metrics to measure progress and identify areas for improvement.

Feedback Loops:

Encourage feedback from employees, customers, and suppliers. It helps to gain insights into your inventory management.

10. Embrace Technology Advancements

Data Analytics:

Use data analytics to gain insights into inventory trends and customer behavior. Predictive analytics can help forecast future inventory needs.

Artificial Intelligence (AI):

Use AI algorithms for demand forecasting, inventory optimization, and decision support. AI can analyze vast amounts of data and make recommendations.

Inventory Management with Microsoft Dynamics 365

Inventory management with Microsoft Dynamics 365 is a game-changer for businesses. This robust software suite provides real-time visibility into inventory. It helps companies maintain optimal stock levels and reduce carrying costs. It ensures products are available to meet customer demands. Microsoft Dynamics 365 has features like demand forecasting, order management, and supplier collaboration. These features help businesses streamline their inventory processes. It makes data-driven decisions and enhances operational efficiency. Whether you’re a small startup or a large enterprise, Dynamics 365 offers a customizable solution for inventory management.

If you want to get professional services of Dynamics 365 for your inventory management, contact us and leave the rest to us.

Conclusion:

Effective inventory management is a complex task, but it can make or break your business. By setting inventory management goals and objectives you can navigate the challenges. This quid will help you to excel in the ever-evolving world of inventory management.

Remember, achieving excellence in inventory management is not a destination; it’s a journey. Stay committed to your goals, adapt to changes in the market, and be open to new technologies and strategies to keep your inventory management practices sharp and effective.